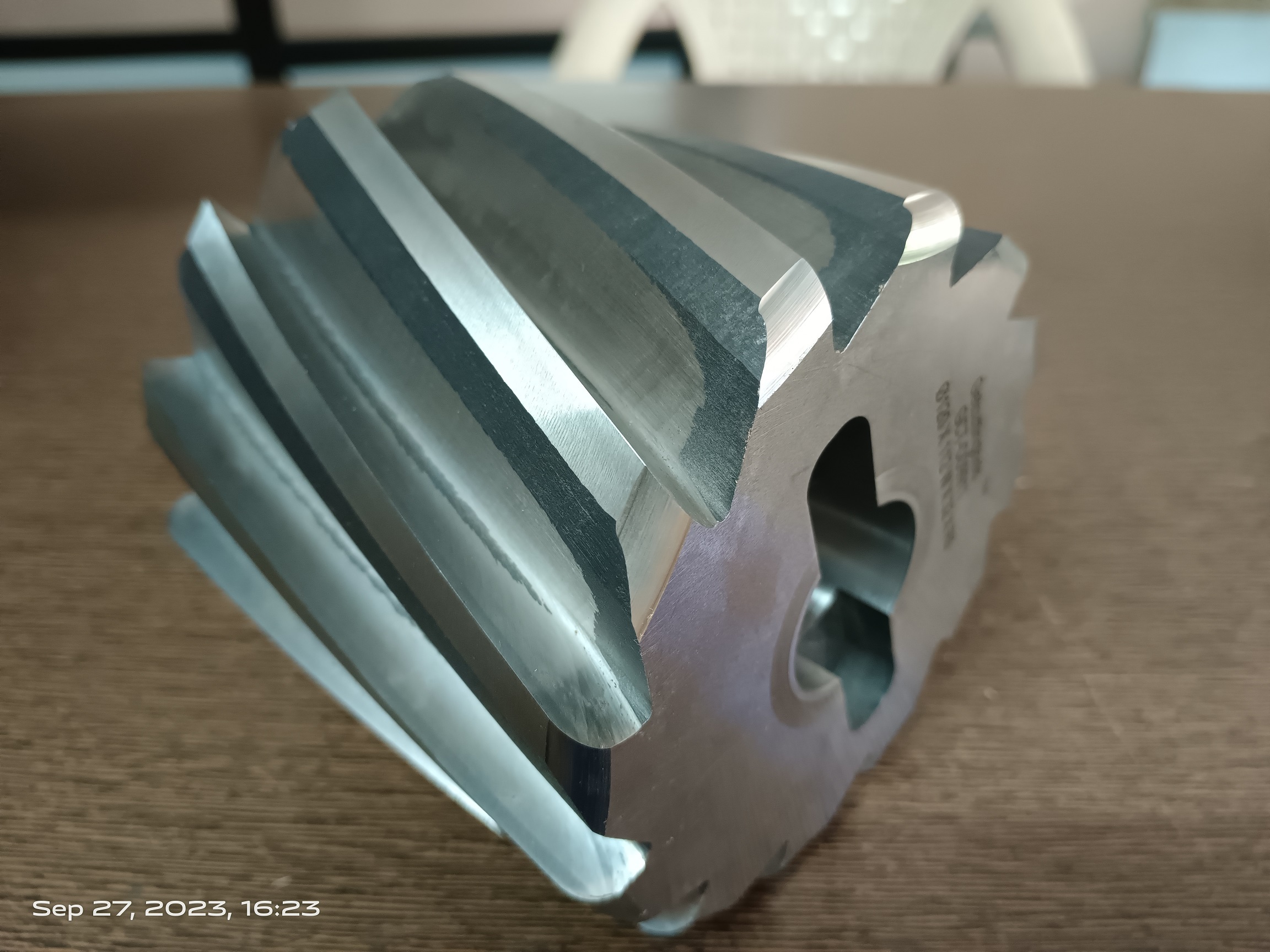

Shell end mill cutter

MOQ : 1 Number

Shell end mill cutter Specification

- Coating

- None/Optional

- Features

- Replaceable Insert Type, Multi-Flute, High Strength

- Tool Type

- End Mill Tool

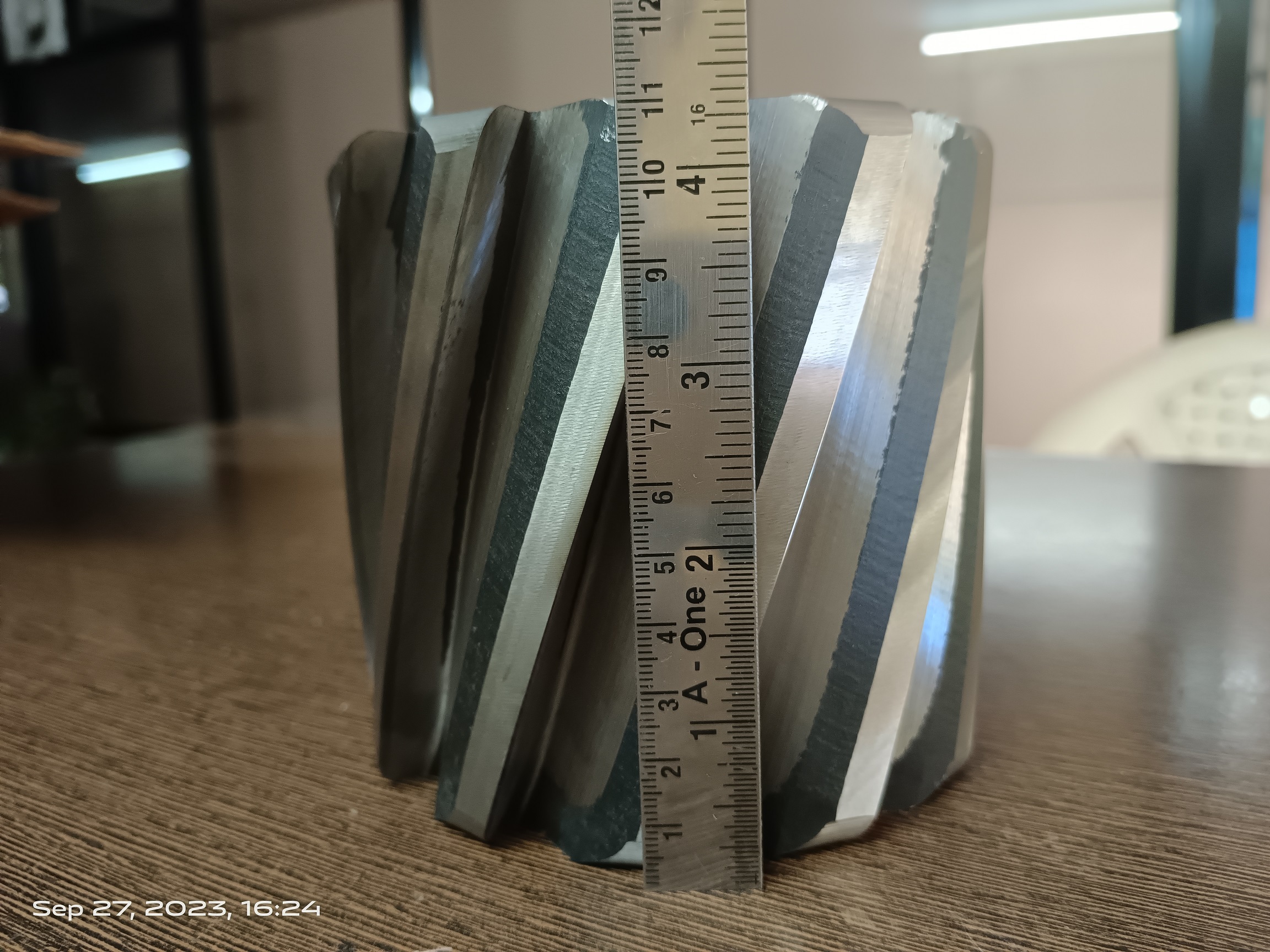

- Length

- 60 mm (approximate as per image)

- Cutting Force

- High

- Cutting Speed

- Up to 250 m/min (Material Dependent)

- Cutting Capacity

- Medium to Heavy Duty

- Cutting Accuracy

- High Precision

- Machine Type

- Milling Machine

- Material

- High-Speed Steel (HSS), Carbide Optional

- Drill Bits Types

- Shell End Mill Cutter

- Hardness

- 58-62 HRC

- Operation Type

- Horizontal or Vertical Milling

- Coating Type

- Uncoated or Custom as Required

- Shape

- Cylindrical with Multiple Flutes

- Operate Method

- Automatic or Manual

- Cutter Type

- Shell End Mill

- Diameter

- 50 mm (approximate as per image)

- Maximum Torque

- Depends on Machine Specification

- Processing Type

- Milling

- Mounting Type

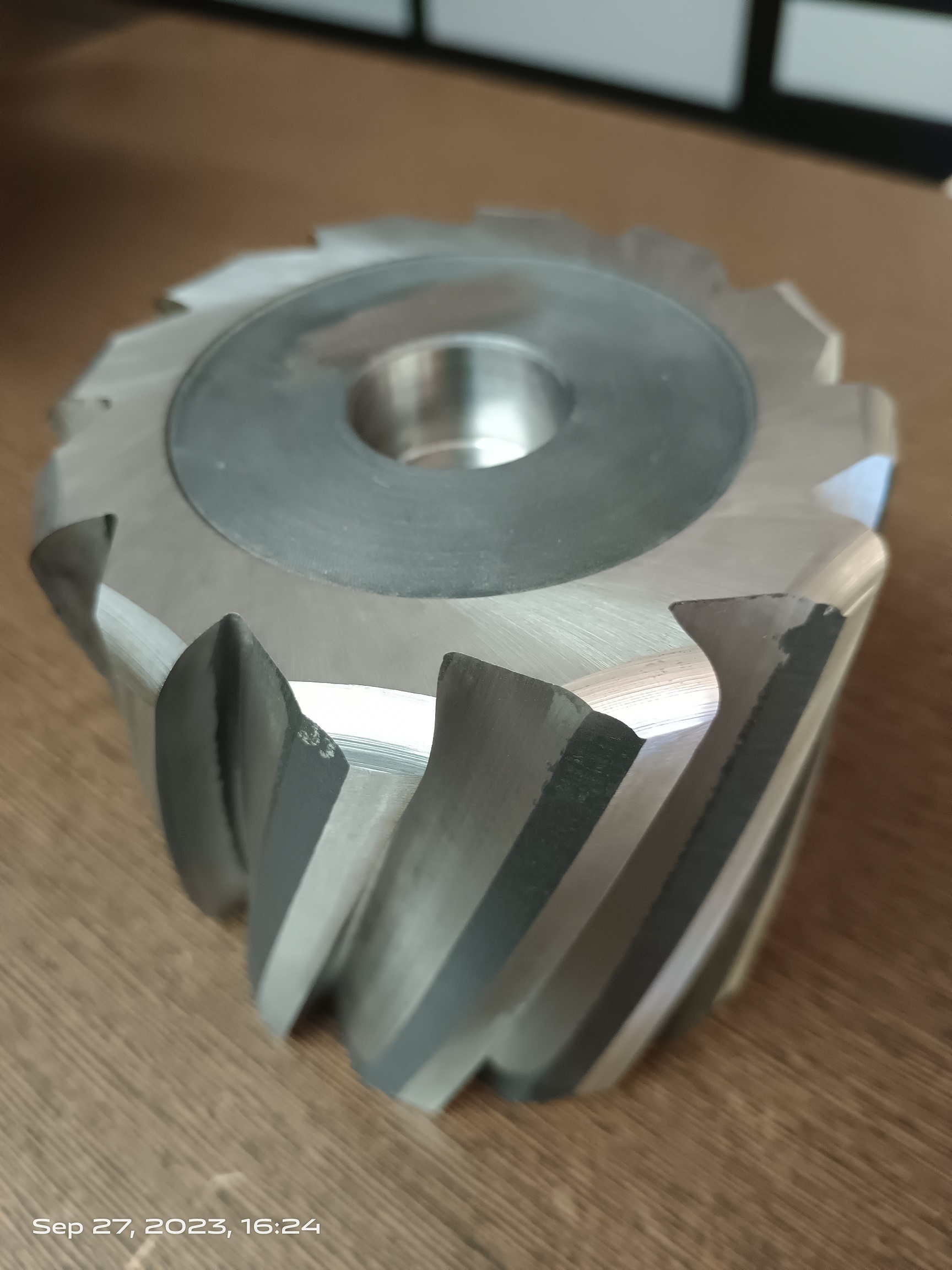

- Shell Type with Central Hole for Arbor

- Replaceable Inserts

- Available (for some variants)

- Compatibility

- Fits Most Standard Milling Machines

- Application

- Slotting, Side Milling, and Face Milling Operations

- Arbor Hole Diameter

- 16 mm (approximate as per image)

- Surface Finish

- Ground

- Number of Flutes

- 6 (as per image observation)

- ISO Category

- DIN 841 Compliant

- Body Treatment

- Heat Treated for Enhanced Durability

Shell end mill cutter Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- Pune

- Payment Terms

- Others

- Supply Ability

- 5 Per Month

- Delivery Time

- 20 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Shell end mill cutter

Experience top-tier cutting performance with our Shell End Mill Cutter-an uncommon tool crafted for glorious precision in slotting, side, and face milling operations. Featuring six meticulously ground flutes, a robust 16 mm arbor hole, and premium heat-treated HSS construction, this uncoated cutter offers exceptional durability and outstanding cutting accuracy. With a 50 mm diameter and 60 mm length, it fits most standard milling machines. Select models offer replaceable inserts for extended usability. Add to Cart now for fresh results in medium to heavy-duty machining-fully compliant with DIN 841 standards.

Shell End Mill Cutter: Unmatched Engineering & Versatile Application

Our Shell End Mill Cutter boasts several special features, including a central hole for easy arbor mounting and multiple flutes for smooth, high-strength performance. The tool's heat-treated body ensures unmatched durability, while optional replaceable inserts add flexibility for different machining tasks. Primed for both horizontal and vertical milling, this cutter performs flawlessly in both automatic and manual operation modes, handling medium to heavy duty slotting, face, and side milling operations with glorious precision.

Domestic Market Coverage & Packaging Excellence

We proudly cater to the Indian market, ensuring frequent dispatching of stock-ready Shell End Mill Cutters to OEMs, manufacturers, and traders. Packaged securely in robust cartons to prevent damage during freight, our cutters usually ship swiftly to meet urgent industrial requirements. Flexible sample policies are available-reach out for individual arrangements or bulk sample requests as required. Trust our supply chain for efficient, reliable delivery from distributor to end-user.

Shell End Mill Cutter: Unmatched Engineering & Versatile Application

Our Shell End Mill Cutter boasts several special features, including a central hole for easy arbor mounting and multiple flutes for smooth, high-strength performance. The tool's heat-treated body ensures unmatched durability, while optional replaceable inserts add flexibility for different machining tasks. Primed for both horizontal and vertical milling, this cutter performs flawlessly in both automatic and manual operation modes, handling medium to heavy duty slotting, face, and side milling operations with glorious precision.

Domestic Market Coverage & Packaging Excellence

We proudly cater to the Indian market, ensuring frequent dispatching of stock-ready Shell End Mill Cutters to OEMs, manufacturers, and traders. Packaged securely in robust cartons to prevent damage during freight, our cutters usually ship swiftly to meet urgent industrial requirements. Flexible sample policies are available-reach out for individual arrangements or bulk sample requests as required. Trust our supply chain for efficient, reliable delivery from distributor to end-user.

FAQ's of Shell end mill cutter:

Q: How do I mount the Shell End Mill Cutter onto my milling machine?

A: The cutter features a central hole with an approximate 16 mm diameter, designed for easy mounting onto standard milling machine arbors. Ensure your arbor matches the hole diameter for secure installation.Q: What applications is this Shell End Mill Cutter best suited for?

A: This tool excels in slotting, side milling, and face milling, handling both medium and heavy-duty operations. Its multi-flute design and high-strength body enable it to process a wide range of materials efficiently.Q: When is it beneficial to use a cutter with replaceable inserts?

A: Opt for variants with replaceable inserts when extended tool life and fast, cost-effective maintenance are priorities. They allow you to quickly swap out worn inserts rather than replacing the whole cutter.Q: Where can I purchase or request samples of this end mill?

A: You can order directly from our stock-ready inventory, and sample policies are available upon request. Contact us for individual or bulk sample requirements-dispatching is quick across India.Q: What makes your Shell End Mill Cutter stand out in terms of durability?

A: Our cutter is heat treated, resulting in a hardness of 58-62 HRC. These treatments, combined with ground surfaces and optional carbide materials, ensure enhanced longevity and resistance to wear.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in End Mill Tools Category

END Mill Cutter

Price 1200 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Carbide

Coating : Polished

Shape : Round

Diameter : 120 Millimeter (mm)

HSS Endmill

Minimum Order Quantity : 3 Pieces

Material : Carbide

Coating : Polished

Shape : Round

Diameter : 120 Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS