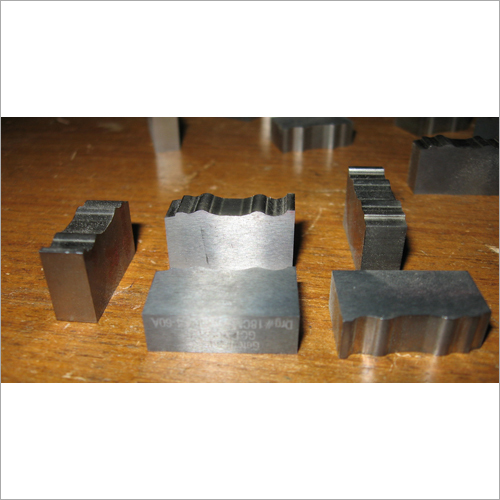

Tungsten Carbide Insert

Tungsten Carbide Insert Specification

- Power

- Manual/Requires Machine Setup

- Tensile Strength

- Approx. 2800 MPa

- Type

- Cutting Tools

- Material

- Tungten

- Weight

- 50 Grams (g)

- Surface

- Polished

- Application

- Metal Cutting, Machining, Turning, Milling

- Feature

- High Hardness, Wear Resistance

- Thickness

- 2.5 mm

- Shape

- Rectangular/Custom

- Coating

- CVD/PVD Optional

- Hardness

- 92 HRA

- Color

- Grey Metallic

- Compatibility

- Lathe, CNC, Milling Machines

- Edge Type

- Sharp, Precision Ground

- Heat Resistance

- Up to 900°C

- Grade

- ISO K20/K30

Tungsten Carbide Insert Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 7-30 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Plastic bag and Bubble wrap

- Main Domestic Market

- All India

About Tungsten Carbide Insert

Our company has sculpted a remarkable place in the market as a reputed manufacturer and exporter of Tungsten Carbide Insert. This insert is mainly used in CNC machines, drilling equipments and cutting machines. To manufacture this insert, best quality carbide and alloy steel is used. We can customize this Tungsten Carbide Insert in different sizes and finishing for clients as per their requirements. We offer this insert at market leading price.

Features:

- High tensile strength

- Dimensional accuracy

- Smooth finishing

Exceptional Durability and Performance

Made from high-quality tungsten carbide and coated with CVD or PVD as optional choices, these inserts exhibit a hardness of 92 HRA and can withstand operating temperatures up to 900C. They provide reliable and consistent performance during heavy-duty machining, supporting extensive usage in industrial metalworking tasks.

Versatile Application Across Machines and Setups

Designed for compatibility with lathe, CNC, and milling machines, these inserts are suitable for various machining processes. Whether used for turning, milling, or general metal cutting, their sharp, precision-ground edge ensures optimal results in both manual and machine-assisted environments.

FAQs of Tungsten Carbide Insert:

Q: How is the Tungsten Carbide Insert typically used in metalworking processes?

A: These inserts are mounted onto compatible machines such as lathes, CNCs, or milling devices, where they serve as the primary cutting tool for turning, milling, and other metalworking applications. Their high hardness and precision-ground edges enable efficient material removal and finely finished surfaces.Q: What are the benefits of choosing a coated Tungsten Carbide Insert?

A: Opting for CVD or PVD coatings enhances the inserts wear resistance, prolongs operational lifespan, and improves cutting efficiency by minimizing friction. The coatings also contribute to higher heat resistance and stability during intense machining operations.Q: When should I use ISO K20 or K30 grade inserts for my application?

A: ISO K20 grade is preferred for finishing and light to medium cutting, offering excellent surface quality. ISO K30 grade is ideal for heavy-duty and rough cutting situations, where higher toughness is needed to withstand demanding machining environments.Q: Where can these Tungsten Carbide Inserts be applied?

A: These inserts are widely used in industrial setups such as manufacturing facilities, workshops, and machine shops across India. They are suitable for various sectors dealing with metal fabrication, including automotive, aerospace, and general engineering companies.Q: What is the process for installing and setting up these inserts?

A: Installation involves mounting the insert securely into the toolholder or machine fixture. Proper alignment and setup, whether for manual operations or CNC programs, ensure optimal contact with the workpiece. It is essential to follow the manufacturers instructions for achieving precise machining results.Q: What makes these inserts advantageous for high-temperature machining tasks?

A: Their robust tungsten carbide base, combined with high-quality coatings, enables these inserts to retain hardness and sharpness at temperatures up to 900C. This property is particularly beneficial for prolonged cutting operations and prevents premature wear under thermal stress.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Profile Carbide Insert Category

Medical Tong Tips

Minimum Order Quantity : 10 Pieces

Surface : Rough

Material : Steel

Product Type : Medical Tips

Type : Crimping Tools

Carbide Inserts

Price 440 INR / Piece

Minimum Order Quantity : 3 Pieces

Surface : Polished

Material : Steel

Product Type : Carbide Insert

Type : Crimping Tools

Customized Insert

Minimum Order Quantity : 10 Pieces

Surface : Polished

Material : Steel

Product Type : Insert

Type : Cutting Tools

Profile Carbide Insert

Price 440 INR / Piece

Minimum Order Quantity : 3 Pieces

Surface : Polished

Material : Steel

Product Type : Carbide Insert

Type : Cutting Tools

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS